Digital Printing

is becoming increasingly popular and offers many advantages. From a technical point of view, it does not require what is known as a printing plate. What does this mean in practice? The data is sent directly to the digital press via a digital connection. The image is printed without the need to prepare a printing form, without wasting materials on setup sheets, and without registration adjustments. Therefore, it allows significant savings in time, resources, and consequently, costs. For this reason, the technology is ideal for print runs of up to a few hundred copies. With low volumes, the cost of preparing plates in offset printing and the waste generated during machine setup significantly increases the price of the order.

Digital printing is strongly recommended for small print runs as well as for projects requiring personalization. Moreover, when it comes to personalized printing, there is currently no real alternative to this technology. Thanks to the direct and immediate data transfer from the controlling computer to the press, it is possible to freely modify names, codes, or serial numbers even during the printing process.

Advantages of Digital Printing

- Fast turnaround – in this case, the term “on demand” takes on its full meaning. Since the process requires no machine setup, uploading a file is enough to start production almost immediately.

- Small print runs – as mentioned earlier, digital printing is unmatched in this category.

- Personalization – currently impossible to achieve with offset presses.

- Competitive price – no printing plates, no setup waste, and reduced use of chemicals result in a much better price for short runs.

- Test copy option – the ability to print a single proof copy, something offset printing cannot provide.

How Does Digital Printing Work?

There are four main types of digital printing: laser printing, inkjet printing, thermal transfer, and sublimation. Let’s take a closer look at how each of them works.

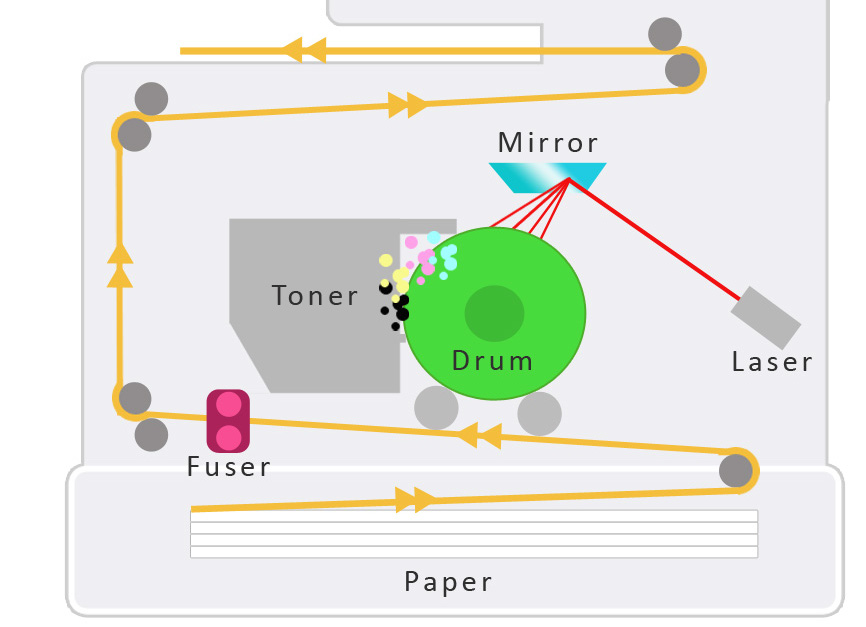

Laser printing – also known as electrophotographic printing. It is the most common type, often found in offices, schools, and universities. Data from the computer is converted, and the printer uses a laser beam to expose an electrostatically charged drum. The latent image is then transferred onto paper using toner powder, and the final fixing is ensured by high temperature.

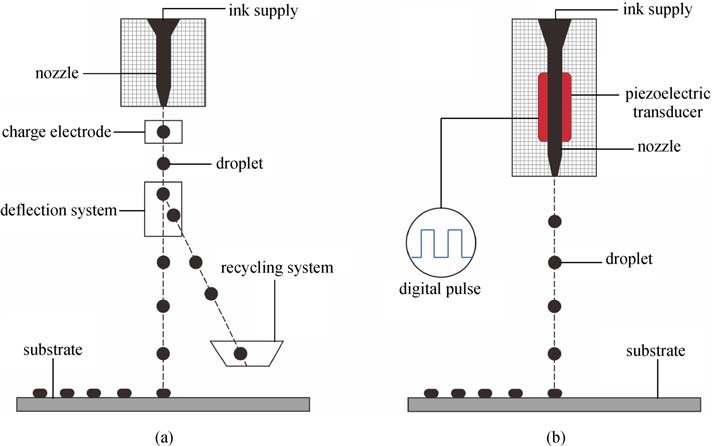

Inkjet Printing – this type of printer is equipped with a printhead and a pressure pump that sprays ink droplets onto the paper surface. The printhead is controlled by impulses from the computer, which allows for precise image reproduction. Within this technology, two methods are used: continuous inkjet (a constant stream of droplets) or drop-on-demand (single impulses). Inkjet technology, as it is commonly known, is applied in industrial, large-format, high-volume, as well as dye-sublimation printing.

Thermal Transfer Printing – a printing house using this technique applies the print onto thermal transfer film. The film is then pressed onto the substrate and fixed with high temperature.

Sublimation Printing – what characterizes this method? It involves printing with sublimation inks. The printer creates an image on a film or transfer paper, which is then pressed onto the substrate and exposed to heat. In this process, the ink penetrates the fibers, permanently dyeing them. The result gives the impression of the print being fused with the treated surface.

Any Disadvantage.. ?

Does digital printing have any drawbacks? Indeed, it does, but compared to its advantages, they are relatively few.

Only a limited number of digital presses can match the print quality of offset machines (although, depending on when you are reading this, this may no longer be the case).

The advantage of having the same cost per piece, regardless of quantity, becomes a disadvantage for larger print runs.

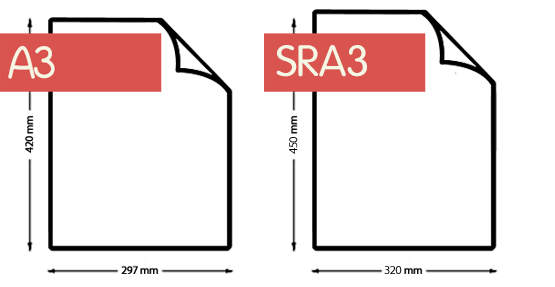

Few machines can handle formats larger than SRA3. (although, depending on when you are reading this, this may no longer be the case)

There is also a limitation when it comes to printing on very high grammage solid board.