Corrugated Board

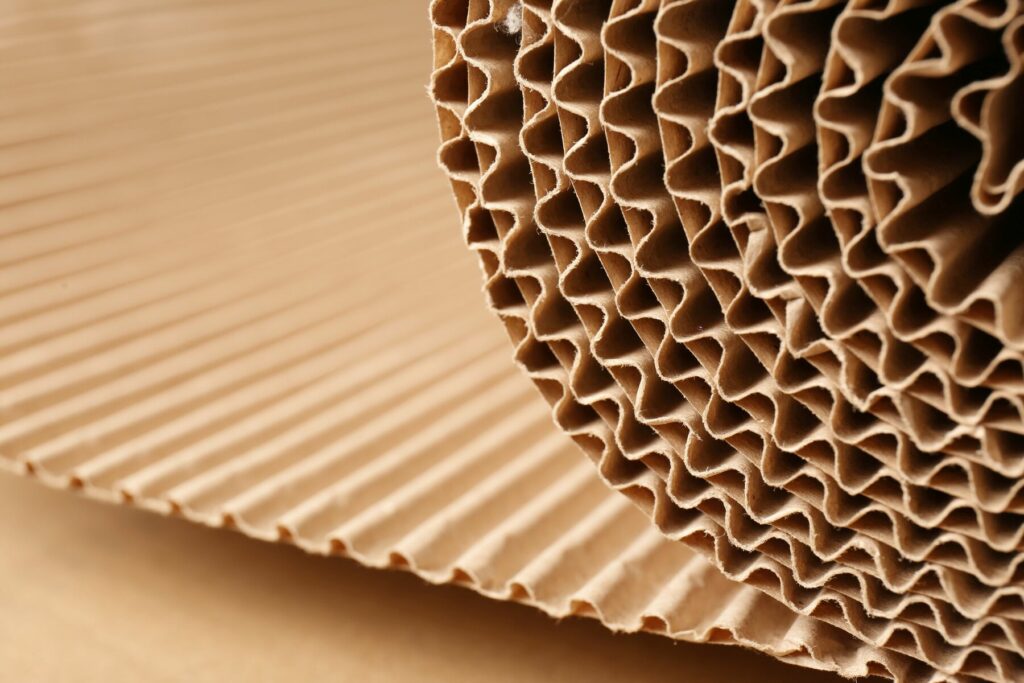

Corrugated board is a material made of two or more layers, usually brown cardboard containing cellulose pulp. One or more layers are corrugated, which makes the material resilient. Thanks to this, corrugated board is lightweight yet very durable. It has wide applications in trade and industry.

History of Corrugated Board

The first production of corrugated board took place in England in 1856 by Edward G. Healy and Edward E. Allen. It was made on a simple machine producing fluted paper using two grooved rollers. Initially, the material was used as padding or stiffening for clothing and hats. In 1874, American Olivier Long improved it by laminating the corrugated paper with flat paper, creating a two-layer board that significantly contributed to the development of the packaging industry.

How Corrugated Board Is Made

It is produced on a special machine called a corrugator, which can reach up to 150 meters in length. Production involves combining corrugated paper (fluting) with flat paper (liner). The fluting is shaped using corrugating rolls. The layers are joined using starch-based glue. This process can be repeated to create boards with varying stiffness and strength.

The Role of Fluting

The direction of the corrugation channels is important because it affects folding and strength. When designing die-cuts (used for cutting packaging), scoring lines (creases) must be positioned with the wave direction in mind. Incorrect orientation may cause difficulties during folding, especially with microflute boards.

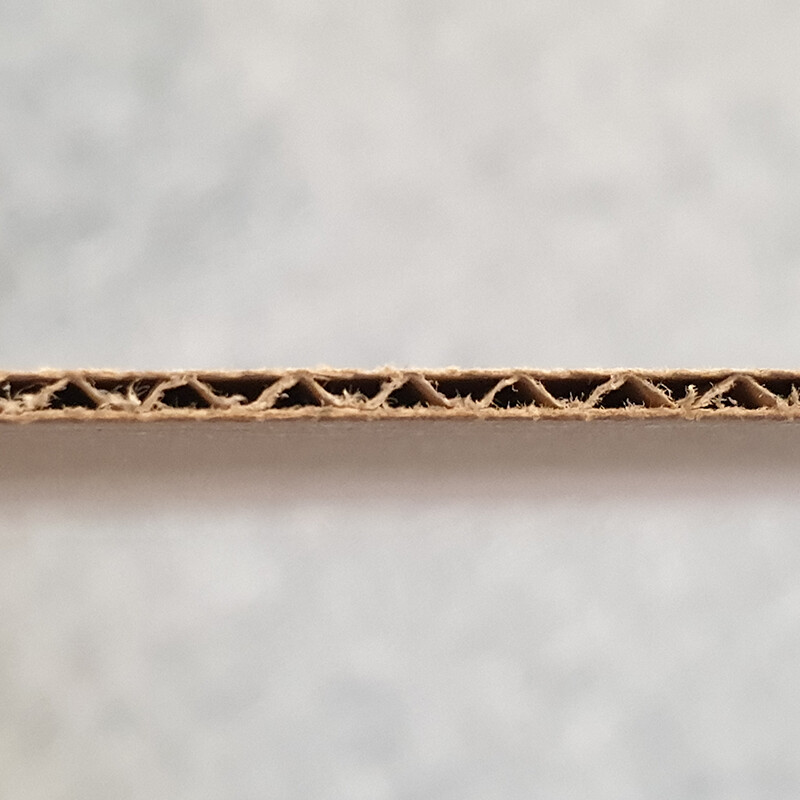

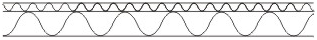

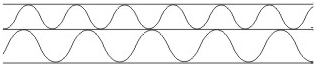

Corrugated Board Flute – Meaning and Application

When we look closely at corrugated board, we can see that the channels between the waves run in one direction and remain parallel. This structure is called the flute in corrugated board. Why is it important? The alignment of the flute directly affects how the packaging folds and how durable it becomes.

In most cases, it matters greatly which side the flute runs parallel to. Imagine a die-cutting tool, a matrix used to cut a package or a wrap. On the die drawing, there are so-called creases – straight lines that compress the material and allow it to bend precisely. Unlike cutting knives, creases have a rounded edge, so they do not cut the board but only compress it.

Therefore, adjusting the flute direction correctly is crucial. If the flute runs parallel to the creases, folding microflute board can become problematic. That is why, when ordering corrugated board, it is necessary to indicate which creases are most important. This ensures the packaging folds properly, prevents production issues, and delivers a neat final result.

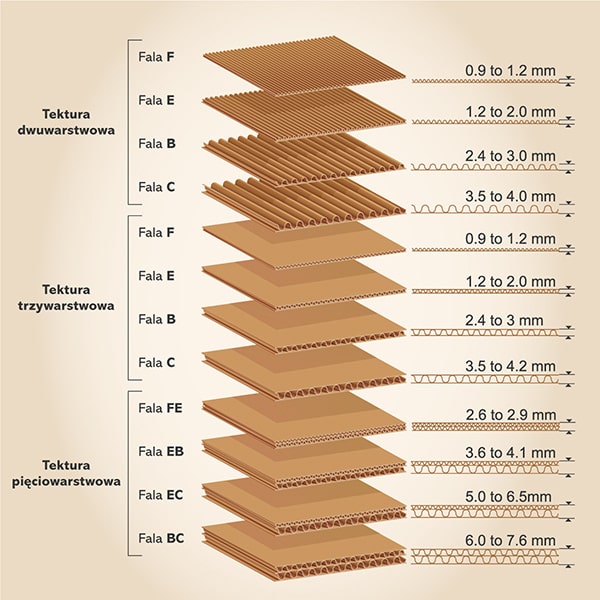

Structure of Corrugated Cardboard – Types and Applications

Corrugated cardboard comes in various forms, from the simplest two-layer version to the most advanced seven-layer type (photo below). Each kind has its own characteristics and uses, depending on strength and printing requirements. Below, we present a detailed description of the most commonly used types.

Two-Layer Corrugated Cardboard

The simplest form consists of two layers: a smooth outer layer – called the liner or sheet, and an inner corrugated layer, which gives the material flexibility. The outer sheets provide strength, rigidity, and suitability for offset printing.

- F Flute: height 0.9–1.2 mm, colors: grey-grey, white-white, white-grey

- E Flute (microflute): height 1.2–2 mm, colors: grey-grey, white-white, white-grey

- B Flute: height 2.4–3 mm, colors: grey-grey, white-white, white-grey

- C Flute: height 3.5–4 mm, colors: grey-grey, white-grey

Two-layer cardboard is used for mass-produced packaging where quality and cost are both important. It can be laminated with prints on MMLiner, Kraftliner, or GD2 boards.

Three-Layer Corrugated Cardboard

Three-layer cardboard consists of two outer sheets and one corrugated inner layer. It is most often used for laminated packaging, flexographic printing, and transport boxes. It can be fully printed or printed in a single color using the flexographic method. Additionally, printed and laminated sheets can be enhanced with foil, UV varnish, embossing, or hot-stamping.

- F Flute: height 0.9–1.2 mm, weight 240–300 g/m²

- E Flute (microflute): height 1.2–2 mm, weight 346–490 g/m²

- B Flute: height 2.4–3 mm, weight 277–580 g/m²

- C Flute: height 3.5–4 mm, weight 400–590 g/m²

Five-Layer Corrugated Cardboard

Modern industry also requires stronger materials that are more challenging in finishing. Five-layer cardboard combines EB or BC flutes, providing high resistance to crushing and mechanical damage.

- EB Flute: height approx. 5 mm, weight 650–850 g/m²

- BC Flute: height 6–7 mm, weight 690–1500 g/m²

Measuring Cardboard Strength

The durability of corrugated cardboard and packaging is determined using specialized testing methods:

- FCT: flat crush resistance – the force needed to crush the flutes when the sheet is placed flat

- ECT: edge crush resistance – the force needed to break a sheet positioned vertically

- BCT: box compression test – testing the box strength between two plates until the side walls collapse

Choosing the right type of corrugated cardboard is essential for packaging quality, durability, and the final product’s appearance. Proper selection of flutes and weight ensures both elegant gift boxes and sturdy transport containers.