Screen printing

Another well-known printing method is screen printing. Importantly, this technique can be applied to many materials, such as paper, cardboard, foil, metal, and even shaped objects. However, it was the clothing industry that contributed the most to its widespread popularity. Screen printing is perfect for covering flat and large surfaces using special screen-printing inks.

What is a Screen?

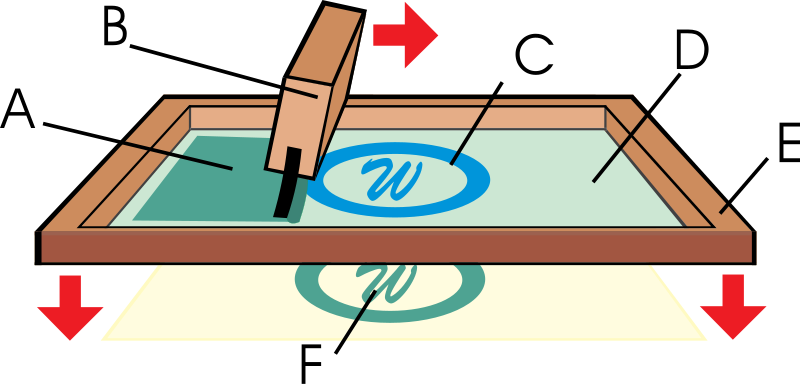

The key element of the entire process – as the name suggests – is the screen itself. But what exactly is it? The process of screen printing always begins with preparing the screen, which is an aluminum frame with a special mesh stretched over it. This mesh plays the most crucial role. Once the non-printing areas are blocked, a ready-to-use stencil is created. Then, the ink is pressed through the open mesh areas. Interestingly, the most commonly used meshes contain between 100 and 150 fibers per cm².

Non-printing areas can be blocked in several ways, including:

- manually applying a solution to the mesh that dries into an impermeable layer,

- drawing with ink or lithographic crayon directly on the mesh,

- using stencils cut from paper or foil,

- coating the mesh with a photosensitive emulsion that is later exposed in a vacuum frame.

The Squeegee

Another essential tool is the squeegee, which presses the ink through the mesh directly onto the substrate. Depending on the specifics of the job, a squeegee may vary in size. It is usually made of plastic, a flexible blade, and a handle. It is also commonly referred to as a scraper.

Inks

When it comes to inks, screen printing uses two main types: water-based and plastisol. Water-based inks contain no PVC or formaldehyde, which is a major advantage. They also allow printing with very dense meshes and deliver vivid, saturated colors.

Plastisol inks, on the other hand, are thicker. This allows them to effectively cover less absorbent or less smooth surfaces. Moreover, they do not dry on the screen during printing, which makes the entire process more efficient.

Less commonly, solvent-based inks, UV inks, and specialized screen-printing adhesives are also used.

Printing Process

The printing process itself is quite simple: the ink is spread across the mesh, and as the squeegee moves over it, the ink is pressed through the open mesh areas onto the substrate. Things are a bit different when printing on round objects. In such cases, the squeegee stays in place while the screen moves and the object rotates.

The latest screen-printing machines are equipped with servo drives that synchronize the speed of the screen with that of the printed object.

A – Ink, B – Squeegee, C – Open part of the mesh, D – Mesh area covered with stencil, E – Mesh frame, F – Printed graphic

History of Screen Printing

The history of screen printing begins in Japan. As early as the 17th century, this technique was used for decorating kimonos. Interestingly, the pioneers of this method are considered to be Yuzensai Miyasaki and Zisukeo Hirose. The first of them decorated kimonos with its use, while the latter created a stencil called katagami. Just like today, the paper pattern was applied to a mesh made of human or animal hair, stretched on a wooden frame. Moreover, on the Fiji Islands banana leaves were used to create stencils – a curiosity that highlights the creativity of different cultures.

With the outbreak of World War I, screen printing began to develop dynamically in the United States. It is worth mentioning that John Pilsworth from San Francisco developed a method of multicolor printing from a single form, which revolutionized the process. Another breakthrough came with the invention of Louis F. D’Autremont – a shellac film called Profilm, which significantly improved stencil preparation. Shortly afterwards, Joseph Ulano introduced a cellulose film to the market, which – importantly – is still used today.

In the 20th century screen printing reached Europe and quickly gained popularity as a printing technique. Furthermore, not long after, serigraphy also appeared as an artistic form, entering schools and studios. It is also worth noting that in Poland, during the 1970s and 1980s, screen printing played an important role in the activity of underground printing houses.

Today, the Polish Association of Screen Printing and Digital Printing, based in Kraków (formerly known as the Polish Screen Printers Association), operates actively. This organization promotes knowledge about screen printing and regularly shares industry news. Importantly, it is also a member of the international organization FESPA.