Offset, offset printing –

– is one of the most well-known and widely used printing techniques. With offset printing, we can produce a variety of products, from leaflets and posters to brochures, magazines, newspapers, and even cardboard packaging, wobblers, or carbonless forms. The high speed of offset machines allows for attractive unit prices while maintaining high print quality and relatively short production times.

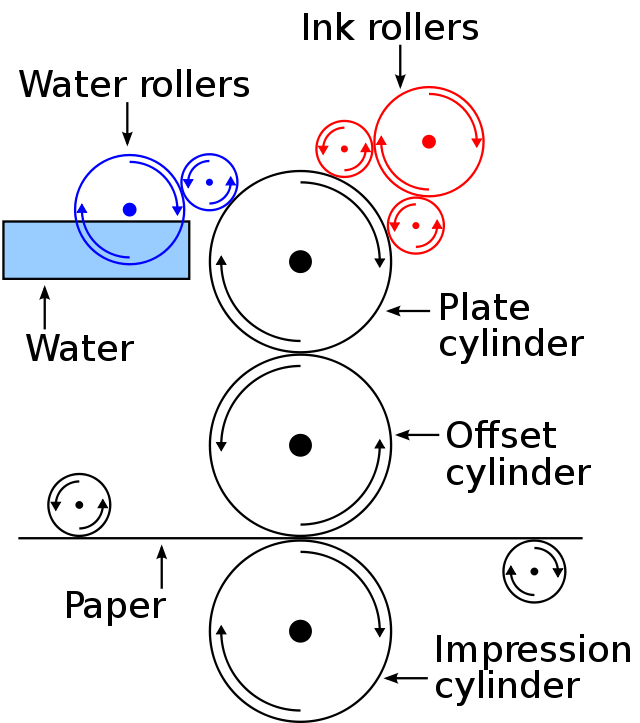

Offset printing works by transferring an image from a printing plate onto the printing substrate via an intermediate cylinder. This cylinder is coated with a layer commonly known as a blanket. In simpler terms, the ink is not applied directly to the paper; instead, it is first transferred to the printing plate cylinder, then onto the intermediate cylinder covered with the blanket, and only then onto the material.

Sheet-fed offset printing

– where the material is supplied as individual sheets of a specific format. Most printing houses in Poland use sheet-fed machines. The sheets are printed with high-viscosity offset inks, which are fixed through absorption and polymerization. After the ink is applied to the sheets, they are transferred to a so-called delivery unit, which stacks the sheets. Even with IR drying or powdering, the stack needs time to allow the ink to properly set on the paper. In web (roll) printing, this process does not occur, which makes production significantly faster.

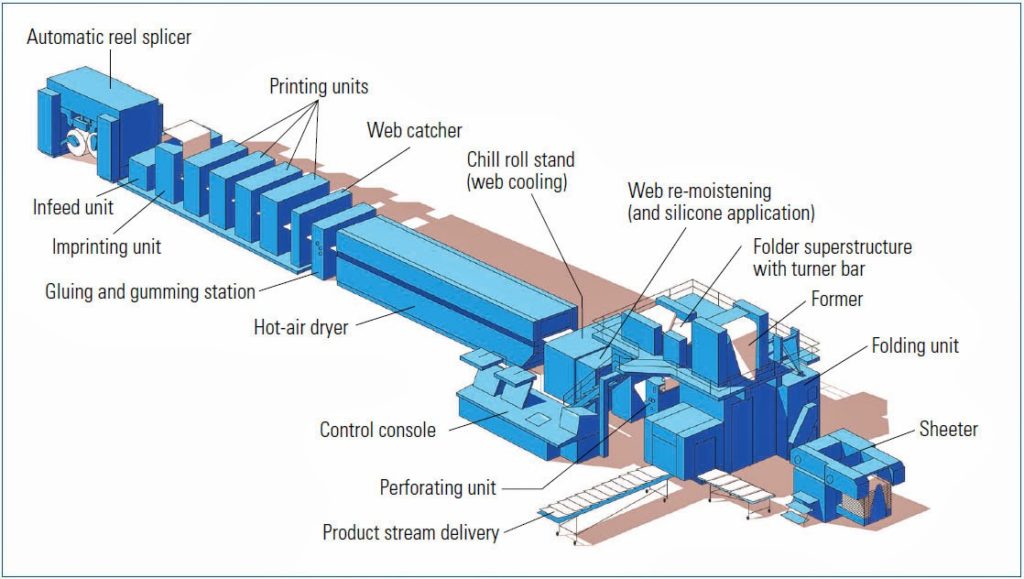

Web (Roll) Offset Printing

– the material is supplied in rolls (commonly called reels) and printed with inks different from those used in sheet-fed offset printing. There are two main types of web printing:

Coldset – as the name suggests, “cold” offset. The ink sets by being absorbed into the paper.

Heatset – “hot” offset. In this process, printing occurs at very high temperatures, where the ink both penetrates the paper and evaporates.

In short, coldset is typically used for high-volume but lower-quality jobs, such as advertising leaflets. Heatset, on the other hand, allows printing on thicker substrates with much higher quality. This technique is often used for high-volume, premium magazines and catalogs. Web presses can operate 3–5 times faster than sheet-fed machines, reducing production costs. Additionally, integrated folding systems can produce nearly finished products directly from the press. Using cheaper roll-stock paper, often calendered or coated, further lowers costs. Overall, the final product is significantly more affordable than in sheet-fed printing.

A Bit of History:

The origins of offset printing trace back to Alois Senefelder (1771–1834). He was the son of an actor at the Royal Theatre and was initially forced by his father to study law. After his father’s death, Alois abandoned law and pursued a career in theatre. Unfortunately, acting was not his calling, and he soon realized this path was not ideal.

Despite lacking acting skills, Alois gained a growing audience for the scripts he wrote. In trying to distribute them, he faced high printing costs and low profits. As a result, he spent a lot of time at printing workshops and eventually began engraving copper plates himself. This was a difficult and time-consuming process because it required creating a mirror image of the intended final result.

One day, his mother asked him to make a laundry list. Without paper, he wrote it on a stone using a mixture of soot, soap, and wax. Alois noticed that water did not stick to the areas covered with this substance, unlike ink. From that moment, he started drawing on stones and then transferring the images to printing plates. Alois patented his invention, becoming the father of lithography (from lithos – stone).