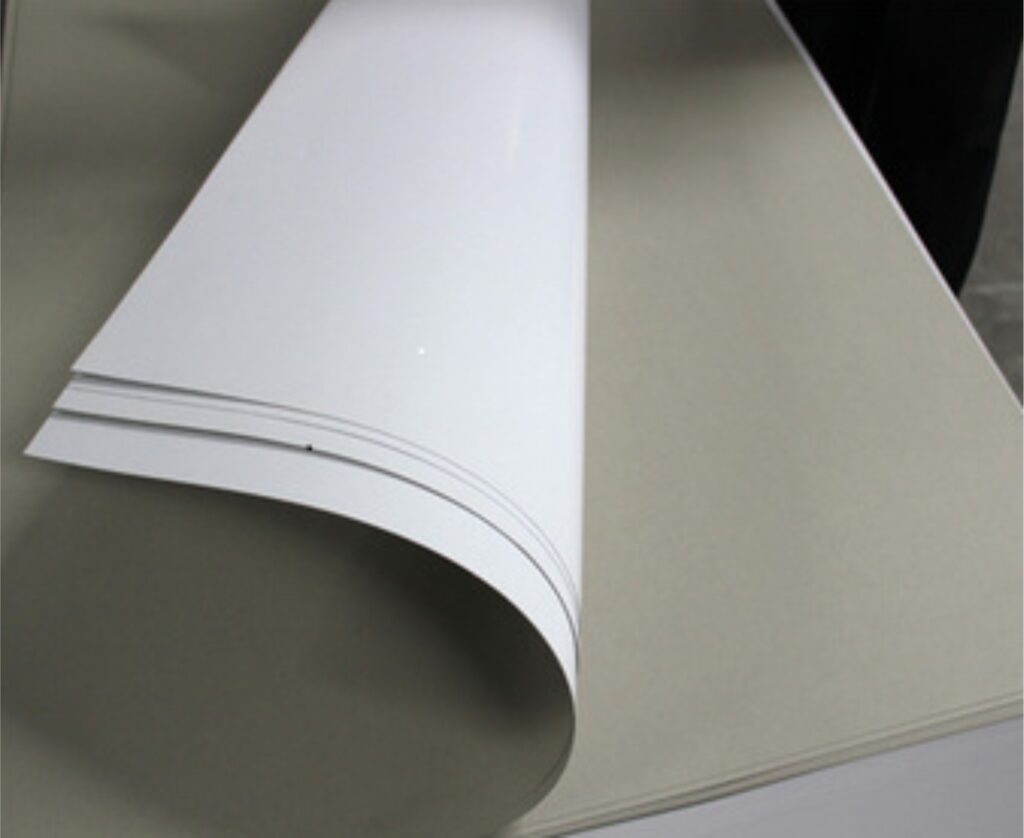

Solid Board – the Most Popular Material for Packaging Production

One of the most commonly used materials for packaging production is solid board. Importantly, it comes in at least three varieties, differing mainly in the reverse side color, stiffness level, and the quality of the coated top surface.

Therefore, to make the choice easier, below we present the three main types of solid boards.

GC1 Board – High Quality for the Premium Sector

GC1 is a premium-grade material, dedicated mainly to the cosmetics, pharmaceutical, and other industries that focus on top quality. Notably, it is characterized by double, and sometimes even triple coating of the external side. In addition, it has an increased level of stiffness, while the inner side is uncoated and white. The most commonly used GC1 board is Arctica 300 g, also known as Alaska White, regarded by many companies as one of the best options in its class.

GC2 Board – Rigidity and Durability at a Reasonable Price

GC2 is a board ideally suited for packaging with moderate aesthetic value. It is distinguished by very high stiffness, even exceeding that of GC1. Therefore, it is recommended for packaging where durability is crucial. Unlike GC1, GC2 has a cream-colored reverse side. What’s more, this type is widely used in the pharmaceutical, cosmetics, food, and display industries. Available grammages are: 250 g, 300 g, 350 g.

GD Board – An Economical Solution

The last type is GD board, the cheapest and least prestigious option. Importantly, it is a recycled board – its top layer is not bright white but grayish. In terms of stiffness, it is inferior to the previous types, which is why it does not work for premium packaging or where high durability is required. The bottom layer is an uncoated gray reverse side. Available grammages are: 180 g, 215 g, 230 g, 250 g, 300 g, 350 g, 400 g. Its only real advantage remains the lowest price.

Summary

To sum up, solid board remains one of the most important materials in packaging production. The choice between GC1, GC2, or GD depends on the expected quality, stiffness, and the purpose of the packaging. Therefore, before making a decision, it is worth carefully analyzing the needs of your brand.